Electrical Installation Wiring Rules (AS/NZS 3000:2018) – Updates

Electrical Installation Wiring Rules (AS/NZS 3000:2018) – Updates

Aug 19, 2018

Updated Electrical Installation Wiring Rules (AS/NZS 3000:2018) includes changes to reflect new technologies, equipment, and installation techniques. This article explores some of the most significant changes presented in the standard, and how they will impact Australian electrical installations.

There is a six-month transition period from 26 June 2018 to January 2019. The transition period will allow electrical contractors and workers to access AS/NZS 3000:2018 Wiring Rules. This can help them with a clear understanding of the changes to electrical installation requirements. Furthermore, these changes will need to be adopted into your businesses installation practices to ensure compliance with this new edition.

Electrical installation work carried out after the transition period needs to comply with these rules, failing which, enforcement action, such as notices or fines, will be issued. Hence, during the transition period the electrical contractors are required to comply with the 2018 edition where possible. The new Wiring Rules also have more detailed requirements to provide mechanical protection to cables in ceiling spaces in positions where they are likely to be damaged.

Safety Switch Requirements (Clause 2.6.3)

The new Wiring Rules require safety switches on all final sub-circuits in domestic/residential installations. This includes fixed electrical equipment like cooktops, hot water systems and also air conditioning units. Out of the existing requirement for a maximum of three circuits per RCD, minimum two RCDs remain for domestic/residential electrical installations.

For non-domestic/non-residential electrical installations, 30mA RCDS shall be installed on all lighting and socket outlet final sub-circuits ≤ 32A (previously it was 20A). 30mA RCDS should be installed on all final sub-circuits ≤ 32A supplying fixed wired electrical equipment. 30mA RCDS shall also be installed on all final sub-circuits supplying fixed wired electrical equipment that may have an increased risk of electric shock, as in environmental conditions like wet areas, and the type of electrical installation and processes being conducted.

Electrical Installation Wiring Rules – Section 1

Section 1 includes many new definitions to provide clarity for the wording of clauses in Sections 2.8. Examples include: ‘arc fault detection device’, ‘electric vehicle’, ‘protective earth neutral’, ‘adjacent’, ‘outbuildings’, ‘alteration’, ‘repairs’ and several others. New ‘Accessible’ and revised ‘Readily Accessible’ definitions provide clarity for installers, especially in medical installations and when mounting electrical equipment.

Switch Room (Clause 2.10)

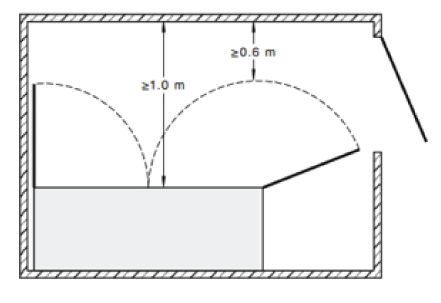

Emergency egress requirements have been improved. Clearances of 1m from accessible faces of closed switchboards and 600mm from open doors or racked-out equipment are required. Switch room door heights and widths have been increased to 2.2m and 0.9m respectively. Two emergency exit paths are required if a switchboard exceeds 800A or is more than 3m in length. Finally, main switches must be manually operated and not controlled by electronic devices.

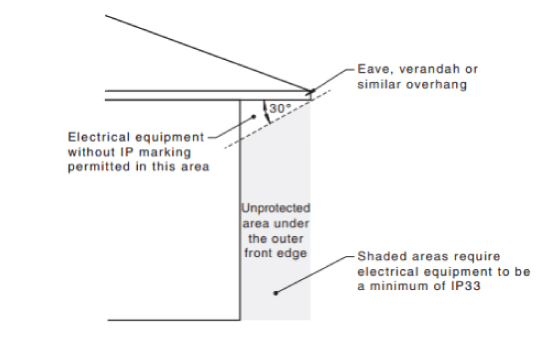

External Influences IP Rating (Clause 4.1.3)

A zone has been created to clarify the IP rating required for electrical equipment mounted on external walls. The zone extends downward at a 30-degree angle from the edge of a veranda or eve to the wall. Equipment mounted in this triangular zone does not require an IP rating. Equipment outside the triangle needs IP33 as a minimum, except for meter boxes which historically have been IP23 rated. Furthermore, any equipment mounted inside meter boxes does not require an IP rating.

Lifts

Lifts used for routine movements of people and goods are considered electrical equipment and are covered in Clause 4.20. Section 7 – Safety Services set out the requirements for designated emergency lifts. This section also deals with supply systems, main switchboard, main switches, fire pumps, fire and smoke detectors and alarms, and air handling equipment.

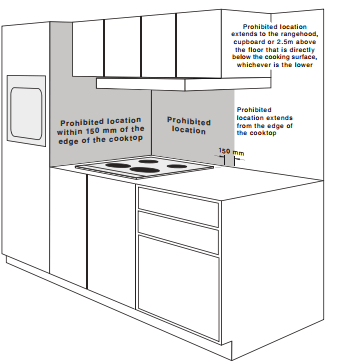

Kitchens, Downlights, Outbuildings and Generators

A 150mm zone either side of the cooktops and extending upward to the range hood, ceiling or 2.4m will apply. Here switches and socket outlets must not be installed. Consequently, this removes the need to reach across hot surfaces.

Clause 4.10: Classifications of downlights must be marked on the light and the packaging to indicate where they may be installed. No classification means they must not be installed. ‘IC’ or ‘IC-4’ lights may be installed anywhere in an installation.

Outbuildings separated by a land area are renamed ‘individual outbuilding’ and ‘combined building’ will refer to more than one structure on a common slab (e.g. several residential units on a single slab).

Clause 6.2 and 6.3 specifies that Generators and network operators’ equipment must not be installed within the zones around swimming pools, spas and water features. Generator systems must also comply with the new version of AS/NZS 3010.

Wiring Rules – Clause 2.9 Arc Faults

Provision for installing arc fault detection devices is a new addition. These two-pole devices detect and isolate circuits experiencing small arcing caused by broken conductor strands in damaged flexible cords and fixed wiring or poor terminations. While the currents generally are small they can lead to fires.

These devices are not mandatory at this time but provide protection additional to circuit breakers and RCD. They are fitted after MCBs and RCDs on final sub-circuits.

New informative appendices (Appendices N, O, P, Q)

- Appendix N Electrical conduits

- Appendix O Installation of Arc Fault Detection Devices

It provides guidance on the selection and installation of AFDDs. This will help to mitigate the risk of igniting an electrical fire in final sub circuits downstream of the AFDD

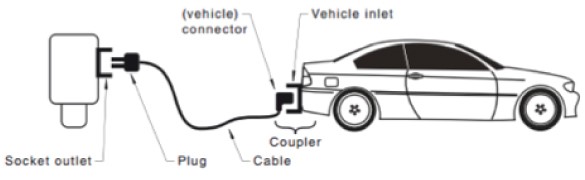

- Appendix P – Electric vehicle charging stations increasingly are being included in electrical installations.

(a) circuits i.e. off-board equipment including the vehicle connector for charging electric road vehicles, with a rated supply voltage up to 1000 V a.c. or up to 1500 V d.c. and a rated output voltage up to 1000 V a.c. or up to 1500 V d.c and

(b) circuits intended for feeding electricity from electric vehicles back into the supply system.

It refers to IEC 61439 ‘Low-voltage switchgear and control gear assemblies’, IEC 62752 ‘In-cable control and protection device for mode 2 charging of electric road vehicles’, and IEC 62196 ‘Plugs, socket-outlets, vehicle connectors and vehicle inlets – conductive charging of electric vehicles’.

- Appendix Q – D.C. circuit protection application guide

Appendix Q deals with control and protection of DC circuits. DC operates much of the equipment in data centres. This is becoming very prevalent in domestic installations with solar panels and storage batteries. It describes requirements for arc suppression, switchgear typing, d.c. ratings, subcircuit wiring/fittings, switchboard locations, and inverters.

Sources: Department of Mines, Industry Regulations & Safety (WA), Workplace Health and Safety Electrical Safety Office Workers’ Compensation Regulator (QLD)

Recent Post

Mar 14, 2024