Correct Practices of Using Barrier Glands in Hazardous Areas

Correct Practices of Using Barrier Glands in Hazardous Areas

Jun 21, 2024

The most common practice for the use of Ex d barrier glands is in flameproof installations, where they are used to prevent flame from any explosion that may occur inside the equipment from travelling down through the cable.

However, for process-connected equipment like instrumentation, where there is only a single process seal, like an O-ring seal in a pressure switch, for example, in contact with fluid or gas under pressure. If the process seal fails, flammable liquid or gas can be forced up into the instrument by the process pressure, and from there travel down through the cable. In this scenario we need to provide a second seal in the wiring to prevent flammables from migrating to the non-hazardous area.

Problems With Cable Construction

The cable glands using elastomeric sealing rings should only be used on cables that are substantially round, compact with an extruded bedding such as in Figure 1 below. However, this cable construction is not always possible especially when it comes to multi-core cables. Figures 2 and 3 show cables that should not be used with glands with elastomeric sealing rings.

Since most cable manufacturers don’t confirm that their cable is circular and compact, a conservative generic approach to the use of barrier glands, has found its way in the HA cable terminations. It is the general interpretation amongst HA practitioners that the cables between the HA and non-HA are terminated using a barrier gland MUST be used in an Ex d environment unless the cables are circular and compact; and have an extruded bedding or sheath.

Most cables would not require barrier glands except for the ones likely to have contact with process flammables e.g. a natural gas actuated electro-pneumatic transducer. Hence in most HA applications like motors, distribution boards etc, the likelihood of gas/vapour transfer from the HA to non-HA is negligible, hence barrier glands are not required.

A barrier gland is used in hazardous areas (HA) when the cable used is not circular or compact, and there is a possibility of an explosion (i.e. pressure + temperature) being generated in an electrical device connected in the HA.

The Changes in AS/NZS 60079.14:2022 from the previous revisions, the use of barrier glands vs. non-barrier Ex d glands in Ex d equipment with arcing/ sparking components are listed below:

1. Cables for fixed installations

AS/NZS 60079-14:2022 Section 9.3.2. states that cables used for fixed installations – shall be sheathed with thermoplastic, thermosetting, or elastomeric material. They shall be circular and compact, and any bedding or sheath shall be extruded. If cables do not pass any one of these criteria and such cables link between a hazardous and non-hazardous area the result may be flammable gas, liquid or vapour migrating through the interstices of unfilled cables to the inside of, for example, control room equipment.

The situation is likely to be most acute with equipment installed in Zone 0 or Zone 1 locations (where the presence of a hazardous atmosphere has a greater likelihood and duration). If these conditions are likely to occur a barrier gland should be used.

2. Ex d – Flame proof Equipment

AS/NZS 60079-14:2022 Section 10.6.2 – requires the use of barrier glands for Ex d installations. Conventional flame-proof Ex d cable glands with seals are designed primarily to retain the explosive pressure within an Ex d enclosure and prevent the passage of hot gasses through the cable entry to the surrounding atmosphere. The design of such cable glands relies on elastomeric seals sealing around the bedding of substantially filled cables to perform this function. It has been established that if cables are not effectively filled, substantially round and compact, hot gasses and pressure produced by an explosion within an Ex d enclosure can bypass the protective elastomeric seals of a conventional Ex d Gland. These hot gases can be forced down the interstices of unfilled cables resulting in the potential damage to the cable and/or connected equipment. The use of barrier glands effectively blocks these explosive gases from migrating down interstices of unfilled cable.

3. Ex nR – Restricted Breathing

AS/NZS 60079-14:2022 Section -10.8 states; “The sealing of restricted-breathing enclosures shall be such as to maintain the restricted breathing properties of the enclosure. Where the cable used is not part of the certificate and/or instruction manual and is not effectively filled, it may be necessary to use a cable gland or other method (e.g. epoxy joint, shrinking tube) which seals around the individual conductors of the cable to prevent leakage from the enclosure”.

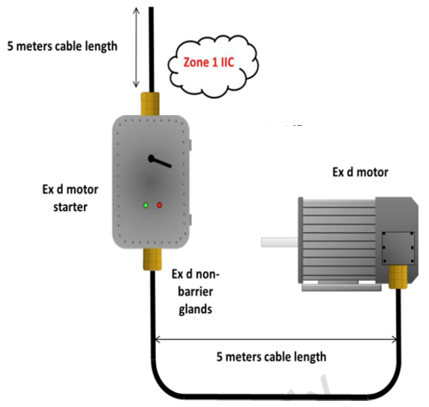

If the cable was deemed as being circular and compact the previous version allowed the use of non-barrier Ex d glands as long as the enclosure was going into a Zone 2, IIB, or IIA environment or in Zone 1 areas in which the enclosure housing arcing/ sparking devices had a volume less than 2 litres. The new standard does away with this and states that if the cable length is at least 3 meters, the use of a non-barrier Ex d gland is now acceptable, regardless of area classification and gas group.

Figure 4: The use of barrier glands and non-barrier glands for direct entry into Ex d enclosures per AS/NZS 60079-14:2022. The issue with cable length is now critical factor of more or less than 3 meters, not the area classification or gas group.

Figure 5: The use of non-barrier glands even in a Zone 1 IIC environment with the connecting cable lengths exceed the 3-meter rule.

Nationally Accredited Training in Hazardous Areas

Our EEHA courses focus on providing students with practical skills and training to select, install, maintain, and inspect electrical equipment in Hazardous Areas, such as gas, dust and explosive atmospheres.

We can provide students with a career pathway in Hazardous Area from UEE42622 Certificate IV in Hazardous Areas, all the way through to the highest vocational qualification in Australia – UEE61222 Advanced Diploma of Engineering – Explosion Protection.

These courses meet the expectations of students who what to make a professional, and well-paying career in EEHA as a subject matter expert (SME) in industry.

For more information and course-related queries, contact us today.

Recent Post

Jul 29, 2024