Programmable Logic Controller (PLC) – What is it, and What are the Benefits?

Programmable Logic Controller (PLC) – What is it, and What are the Benefits?

Jan 04, 2023

From generating electricity to producing food, many of the most critical industrial processes today are performed by automated machinery. Our ability to innovate and produce has been boosted by automation technology. However, our current level of automation is only possible with the invention of the programmable logic controller (PLC).

What Is a Programmable Logic Controller?

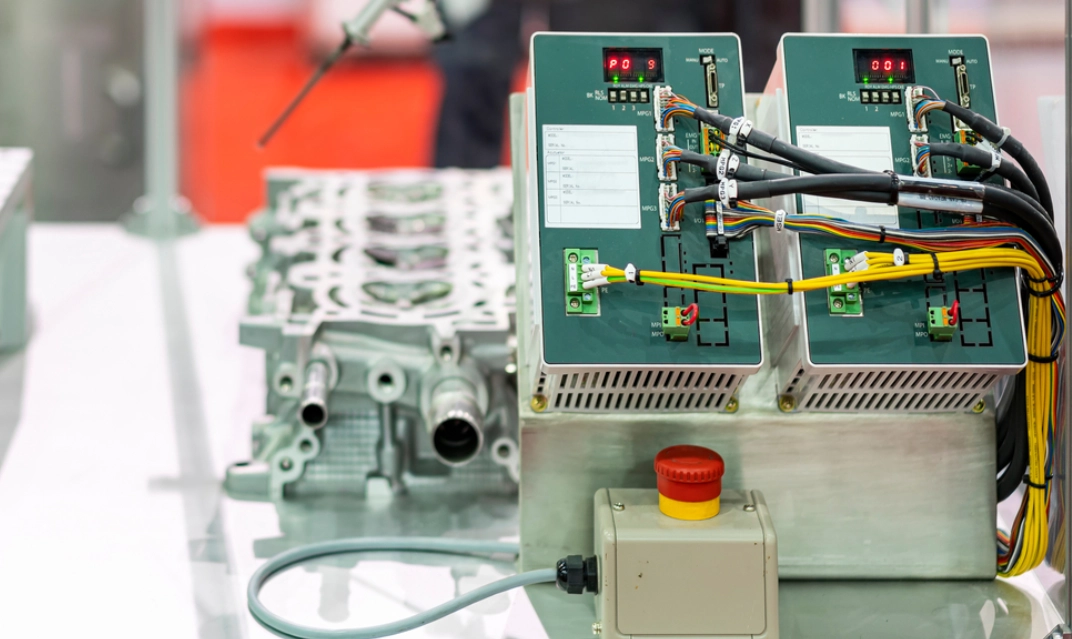

A programmable logic controller is a small computer with inputs for data and outputs for sending and receiving commands. A PLC’s primary duty is to regulate a system’s operations using the underlying logic that has been programmed into it. PLCs are used by businesses all over the world to automate their most crucial procedures.

A PLC takes in inputs from automated data capture points or human input points such as switches or buttons. Based on its programming, the PLC decides whether to change the output. The outputs of a PLC can manage a wide range of machinery, including motors, solenoid valves, lighting, switchgear, safety shut-offs, and many more. PLC locations might differ significantly from one system to the next.

What are the advantages of using PLCs?

For many years, PLCs have been a required component in industrial machinery design. Wonder why?

- Programming PLCs is relatively intuitive. PLCs are a great choice for businesses looking to minimise complexity and costs because their programming languages are simple.

- The PLC technology is well-tested and has been analysed for years. Numerous PLC types are available online, and comprehensive tutorials for programming and integrating them.

- Small businesses and start-ups often use PLCs because they are available at various price points.

- The versatility of PLCs makes them suitable for controlling a wide range of processes and systems.

- As solid-state devices, PLCs do not contain any moving parts. As a result, they are extremely reliable and able to withstand the challenging conditions found in many industrial facilities.

- In addition to being easy to troubleshoot, PLCs have relatively few components.

- In addition to being efficient, PLCs consume very little electricity. In addition to saving energy, this may simplify wiring considerations.

What is the application of PLC?

A few uses for programmable logic controllers (PLC) are:

- In civil applications, it controls traffic signals, elevators, and washing machines.

- Aerospace uses it for quenching water tanks.

- It is used to reduce the human control allocation of technical equipment, called automation.

- It is used in chemicals, cement, food, and paper industries.

- The burner management system uses it to control purging, pilot light off, flame safety checks, main burner light off and valve switching for fuel changeovers.

- It is common in the printing industry to use a print register control system on an offset web press and a multiple-stage screen washing system.

- The system monitors escalator operation and safety control in the travel industry.

However, as the need for PLC systems increases, the demand for people who can provide smoother assistance increases. This is where PMV can help by offering courses and assisting with industry upskilling. These are the courses that PMV offers:

PLC Automation Short Course – Basic

Participants in the PLC and automation training will configure the controller and HMI hardware, write simple programmes, test them, and troubleshoot them. Operator control, status indication, alarms, and equipment maintenance policies are all functional needs.

PLC Training – Automation Short Course (Advanced)

During this PLC course, the Siemens S7-300 series controller will be used to design, test, and troubleshoot programmes for sequential process applications. Operator control, status indication, alarms, equipment maintenance policy, process data, fault diagnosis, and safety policy are only a few of the functional needs.

Recent Post

Mar 14, 2024